IMPLEMENTATION OF VACUUM EVAPORATION IN PUERTA DE HIERRO HOSPITAL FROM MAJADAHONDA

16-01-2020

THE HOSPITAL

The Puerta de Hierro Hospital was founded in 1964. In 2008 it was moved to his current building located in Majadahonda in the community of Madrid.

With a constructed area of 165,000m², it has more than 600 single beds, 22 operating rooms and provides healthcare to more than 550,000 habitants of the Community of Madrid.

This makes it one of the most important hospitals in our country and a reference in the hospital sector.

THE ENVIROMENTAL PROBLEM

Hospitals generate wastewater containing traces of chemicals, drugs: soaps, cleaning products and disinfectants, also blood, urine, alcohols, traces of organic solvents, physiological serum, and other toxic elements, which must be treated before being discharged to the sewer.

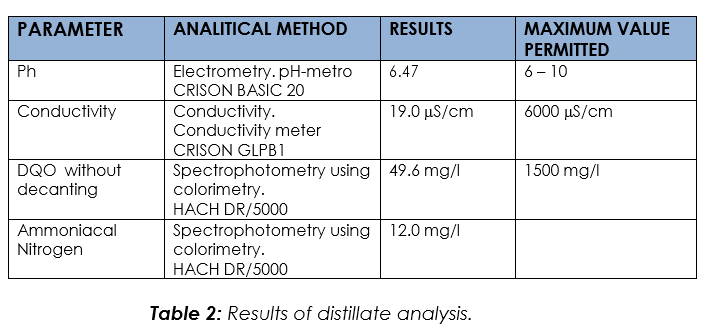

In the case of the Puerta de Hierro Hospital approximately 2-3 tons of wastewater are generated daily, which have a composition with the following characteristics:

Due to the complexity of the composition of these waters, is necessary an external management or treatment at the plant, before the discharge.

THE SOLUTION

To begin to propose a solution to the problem, the Concessionary Society of the Puerta de Hierro Hospital asked C&G Ibérica to analyze the feasibility of treating this water by installing a vacuum evaporator. For this, C&G Ibérica made an adequate sampling of the wastewater that was being generated given the activity of the Puerta de Hierro Hospital.

Once the most critical parameters were confirmed, different laboratory tests were carried out, in order to differentiate between those that gave a better final water quality and a more favorable mass balance.

Taking into account the circumstances of implementation, the suggested dimensions that limited the space, and the needs of the client for a total automation and the reuse of water, C&G Ibérica proposed as a solution, the installation of a Vacuum Evaporator Model V-NT 4,000, built in SAF for the treatment of wastewater produced in all the installation.

This solution was accepted by the Engineering Service of the Puerta de Hierro Hospital and implemented afterwards.

Vacuum Evaporation is a technology that allows you to concentrate wastewater from various industrial processes at a low energy cost.

Image 1: Vacuum Evaporation model V-NT 4.000.

GLOBAL OPERATION

By lowering the system pressure to vacuum conditions (33 mbar); the boiling temperature of the aqueous solution to be treated / evaporated is reduced.

In this way, the amount of calories needed for the evaporation process is much lower than in atmospheric pressure conditions.

Through vacuum, the system automatically aspirates the contaminated water to be treated. Once the water reaches the boiler, it receives heat thanks to a lower exchanger through which hot coolant gas circulates at high pressure.

The vapors generated in this first stage, reach the top of the boiler, where they give their heat to a second exchanger, through which the same cold gas circulates at low pressure and condenses as clean water: Distill. This distill, is transparent water, with very low conductivity and no suspended solids. It represents more than 95% of the treated water, and can be reused in industrial processes or discharged respecting the current regulations.

As a counterpart to the distill, a mud is obtained where all the pollution accumulates: Concentrate.

OPERATING DIAGRAM

Image 2: Vacuum evaporation operating diagram.

RESULTS

Mass balance

The installed evaporator capacity exceeds 4,000 liters / day of treatment.

Currently, cycles of approximately 50 tons of treated water are being carried out, of which we are currently leaving an amount of less than 1% (400 kilos) of concentrate (rejection), which must be managed through an approved company.

Thanks to this system, more than 97% of the water treated is being recovered in the form of high purity distillate. Actually, as an environmental measure, this water is being used to water the hospital gardens generating savings.

We are still optimizing the process to reach the least possible amount of waste to external management.

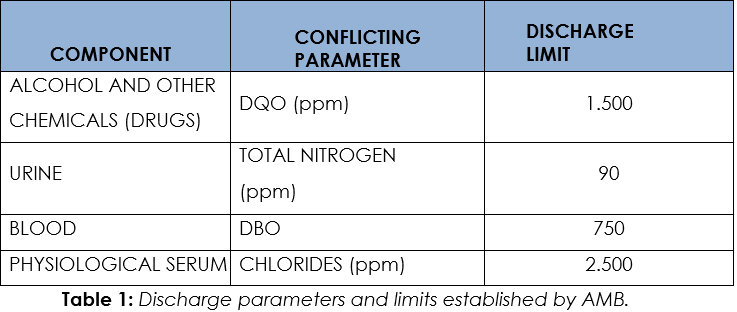

Distill analysis