REVERSE OSMOSIS REJECTION: THE GREAT IGNORED

08-11-2019

Reverse Osmosis is a well extended technology used to obtain demineralized water needed in certain industrial process. But, is this technology efficient? To our knowledge is not for itself.

Reverse Osmosis needs to be reinforced with some complementary technology that enhances its efficiency in the masses balance, decreasing the generated rejection and increasing the percentage of permeate. At this point is where the Vacuum Evaporators manufactured by C&G come into play.

Evidently, reverse osmosis function is vital in an industry that needs more pure water that the one that reaches our factories, but aren’t we forgetting about something? The great ignored, that for us is the main character in this equation: THE REJECTION.

In times of drought, that is unbearable in some areas of our planet, a rejection that still contains more than 95% of water is being considered as good, considering this as non utilized water and being discharged even outside the establish discharge limits.

The complete masses balance shows that osmosis allows us to obtain more pure water as a qualitative result. On the other side we see that in order to obtain one litre of osmotized water, at least 3 litres of domestic water are consumed, around 2 litres in small installations and 1.5 in major industrial plants.

In the last year, there has been a development in membranes that allows working with higher pressures (80-90 bares approx.) and produces a rejection of only 10-15%, but this rejection continues to have more that 90% of water. Water a fundamental resource for life which is expected to be scarce in the near future.

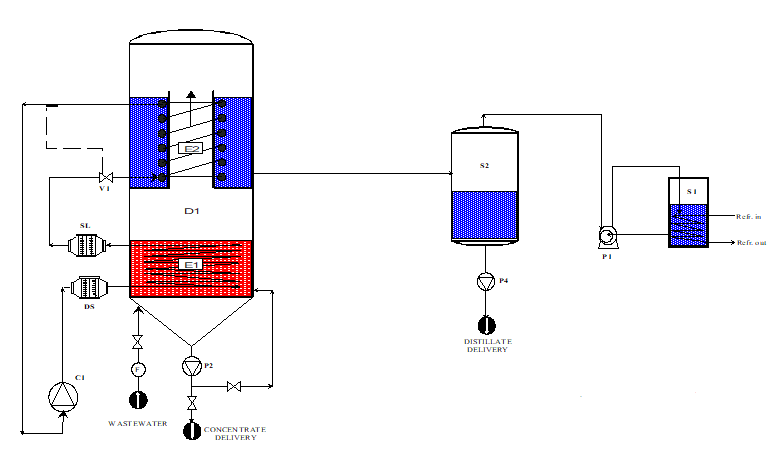

Image 1: Reverse osmosis

C&G IBERICA proposal is clear: to concentrate this rejection until we reach dry residue. That is the only way to recover 100% of the water.

V-NT MODEL

Vacuum evaporator model V-NT, is a machine that works with the heat pump principle, they are vertically developed with an immersed coil as the principal exchanger.

One of the main characteristics of this equipment is its concentration capacity until a saturated residue in the form of salts that will continue to be pumpable. This will allow us to discharge in an automatic way guaranteeing lower costs of exploitation and the greatest efficiency in the whole process.

The system works with vacuum which guarantees the minimum energetic consumption.

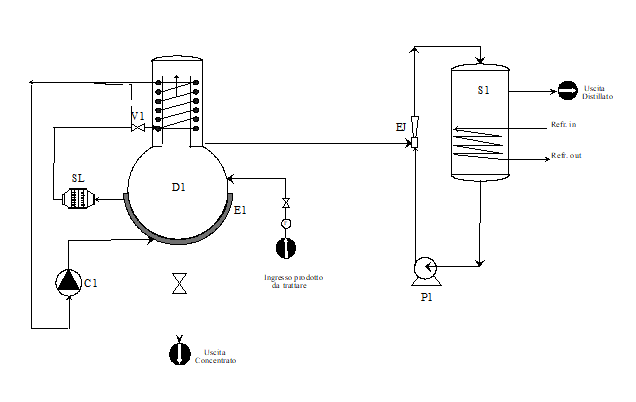

Image 2: Functioning diagram of the Vacuum Evaporator V-NT

The machine core, of the V-NT, is constituted by a refrigerating system that takes the high pressure line, in order to transfer heat to the wastewater until it reaches boiling point, and the low line pressure to condensate the distil product extracting heat.

This extraction system provides a residual pressure inside the evaporator of 33 mbar.

C&G vacuum evaporators can work up to 24 hours without stopping and without needing the presence of a operator thanks to the management of the PLC.

V-NT VACCUM EVAPORATOR CHARACTERISTICS:

- Every component is from the best European brands.

- The boiler is manufactured in Inox 316L and removable in 4 parts.

- Treatment capacity up to 15-20% more that the nominal value.

- Liquid ring system (high efficiency vacuum).

- Automatic distil discharge through centrifugation pump.

DRY MODEL

Vacuum evaporators DRY model, is a machine that works with the heat pump principle, they are horizontally developed and with an external shirt that provides heat.

This configuration allows reaching a dry residue and in consequence completing the work circle with the maximum minimization of the residue and the major saving in comparison to the external management.

The system works with vacuum guaranteeing the minimum energetic consumption.

This dry residue is not pumpable and its discharge must be done manually through the door located in the boiler.

Image 3: Functioning diagrams Vacuum Evaporator DRY.