RS vacuum evaporators

RS vacuum evaporators

The RS vacuum evaporators are developed vertically with heat pump technology.

With the boiler located in the lower part and fed with an external jacket, allows us the installation of an internal scraper that prevents residue to deposit in the internal walls of the boiler.

With this system we can reach high concentrations in the final waste, keeping a good performance throughout the whole process and with bigger capacity that the ES- DRY series.

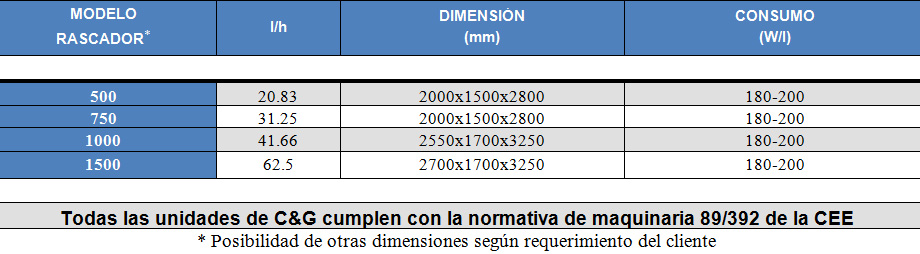

Series:

- The best European brand selection for every component of the equipment.

- Inox. 316L dismountable in 4 parts boiler.

- 15%-20% more capacity that its nominal value.

- High efficiency vacuum system (liquid ring).

- Automatic discharge of the distilled through a centrifugation pump.

- Constant agitation of the concentrate with a scraper blade.

- High concentration power (1400-1500 g/l).

- Touchscreen, internet connection and data registry.

Optional:

- Distill conductivity control.

- Digital flowmeters for masses balance recording.

- Automatic cleaning of the inferior coil.

Description of the operation

RS vacuum evaporators are vertically developed with a boiler in the lower part and a distill recondensation boiler in the upper part.

The system works under vacuum guaranteeing the minimum energy consumption.

The presence of an internal scraper allows the constant cleaning of the internal part and a greater viscosity of the treated product.

The distance between the level of effluent to be treated and the condensates recollection tray, guarantee the absence of drag and in consequence a high pure distilled.

Cold Circuit

V-NT evaporators work with heat pump technology.

The core of the machine has a refrigeration system that uses the high pressure line to transfer heat to boil the wastewater, and the low pressure line to condensate the vapors produce in the lower part of the boiler.

The high pressure line is conducted to the interior of a jacket located on the exterior of the boiling chamber, in a way that doesn’t interfere internally in the work of the scraper.

Vacuum Circuit

In order to achieve the necessary vacuum inside the boiler a system of a vacuum liquid ring pump and a high performance injection is use.

This extraction system produces a residual pressure inside the evaporator of 33 mbar.

Distill Circuit

The distill discharge is made independently. In our V-NT equipments we have a storage tank that is constantly emptied by means of a centrifugation pump.

Concentrated Circuit

This type of system allows reaching high concentrations, obtaining practically dry waste.

The discharge of the concentrate is done manually through a spherical pump located in the lower part, facilitating the scraper´s movement that at the moment of discharge rotates specially close to the outlet valve.

If the client wants, an automatic discharge pump can be installed.

Automatization, alarms and control.

C&G evaporators can work 24/7 without necessary control, thanks to the management of the PLC.

The easy and intuitive configuration of the software allows and easier reading and an immediate configuration of the working parameters.

The use of a screen (Standard from V-NT 1000) guarantees an efficient and quick global control of the machine.